With the increasingly stringent environmental protection policies, traditional coal-fired boilers are gradually being phased out in many industries. As a clean energy alternative, biomass gasification boilers are gradually accepted by various industrial enterprises. Today, we take Jiangxi ET brick factory as an example to discuss the application of biomass gasification boiler in brick factory and its cost benefit.

- Industry background and demand

As an important part of the building materials industry, brick factories require a large amount of heat energy for their production process. Traditional coal-fired boilers, although low-cost, are highly polluting and no longer meet modern environmental requirements. Biomass gasification boilers utilize renewable biomass fuels, such as crop straw, wood chips, bark, etc., which not only provide the required heat energy, but also have the advantages of environmental protection and low carbon.

- Technical characteristics of biomass gasification boiler

Biomass gasification boilers convert biomass fuels into combustible gases through high-temperature gasification reaction, and then generate heat energy by burning these gases. Compared with traditional coal-fired boilers, biomass gasification boilers have the following advantages:

Superior environmental performance: the sulfur dioxide (SO2) and nitrogen oxides (NOx) content in the exhaust gas emission of biomass gasification boiler is lower, which reduces the formation of acid rain and haze.

Low fuel cost: biomass fuel is widely available, relatively stable in price and lower in cost than coal.

High thermal efficiency: with optimized design and efficient combustion technology, the thermal efficiency of biomass gasification boiler can reach more than 80%.

- Application case of Jiangxi ET Brick Factory

Jiangxi ET Brick Factory introduced an 8-ton biomass gasifier (investment amount of 8 million yuan), equipped with SCR denitrification system to ensure that the emissions comply with environmental standards. Through practical application, the brick factory has achieved significant economic and environmental benefits.

*** Translated with www.DeepL.com/Translator (free version) ***

| Project | Data |

|---|---|

| Nitrogen oxide (NOx) emissions | 220 mg/m³ |

| Sulfur dioxide (SO2) emissions | 80 mg/m³ |

| Carbon monoxide (CO) emissions | 435 mg/m³ |

| Particulate Matter (PM) Emissions | 330 mg/m³ |

| investment amount | Eight million RMB. |

| Boiler Specifications | 8-ton biomass gasifier |

- Cost-benefit analysis

After investing in biomass gasification boiler, the brick factory not only realizes clean production, but also significantly reduces the operation cost. The specific benefits are analyzed as follows:

Lower fuel cost: Compared with the traditional coal-fired boiler, the cost of biomass fuel is lower. Calculated at 400 RMB per ton of biomass fuel, the fuel cost can be saved about 2 million RMB per year.

Reduction of environmental protection fines: As the exhaust gas emission is up to standard, the environmental protection fines due to over-standard emission are avoided, which can save about 500,000 RMB per year.

Increase corporate image: The use of biomass gasification boiler enhances the green image of the company in the market, which helps to get more orders and customer recognition.

Policy subsidies: The national and local governments have certain policy subsidies and tax incentives for enterprises adopting clean energy, and they can get about 300,000 RMB per year.

- Graphical analysis

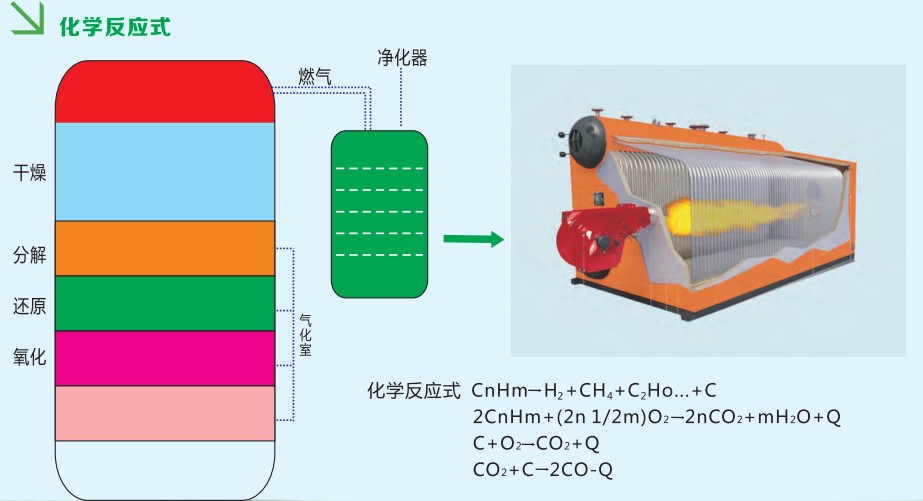

The following figure shows the working principle of biomass gasification boiler and its application in brick factory:

Through the illustration, we can clearly see the process of gasification, combustion and heat utilization of biomass gasification boiler, as well as the comparison with traditional coal-fired boiler.

6 Conclusion

The introduction of biomass gasification boiler in Jiangxi ET brick factory not only meets the environmental protection requirements, but also realizes significant economic and social benefits. By optimizing fuel costs, reducing environmental fines and enhancing corporate image, the brick factory has gained a greater advantage in the competitive market. The popularization and application of biomass gasification boiler not only helps the development of the enterprise itself, but also contributes to the realization of the "double carbon" goal.

In the future, we expect more enterprises to pay attention to and adopt biomass gasification boilers, and jointly promote green development and achieve sustainable economic growth.